Miracle Truss® Buildings are built-to-order, in one of the most efficient factories in the country, with almost 40 years of steel engineering expertise backing our design. Made from 100% American steel, and fabricated by certified welders, we strive to provide you with the best in quality and design. Every building is jig-built and factory test assembled to ensure proper fit prior to being shipped directly to our customers across the U.S and offshore, so you can rest comfortable knowing you are taking delivery of one of the highest quality steel truss building kits available. Further upheld by our industry leading 50-year Frame Warranty, your Miracle Truss® Building will be just as beautiful as it is strong.

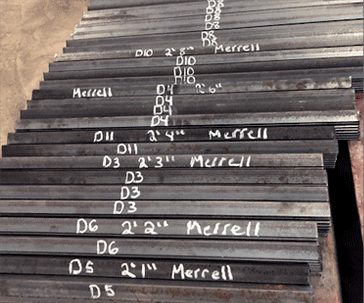

Steel trusses and components are manufactured from the ground up for each project.

Every plate, connection point, tab, and component is made in-house. 100% USA made.

Our steel clips are hand made and formed in a “C” shape (not just a flat plate), this holds the wood purlins and girts into place both on the top and bottom of the board to help eliminate twisting.

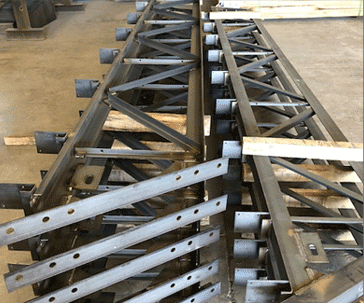

The webbing for every Miracle Truss® building is made of structural angle – no round stock here! We feel this creates a stronger, better, and more consistent product giving you more value for your money. No corners cut.

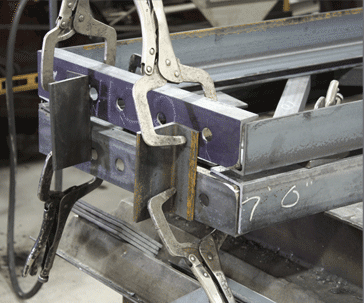

Every truss is jig built and mocked to ensure a quality, accurate fit every time. This means you will have a proper fit and installation will be a breeze – DIY friendly!

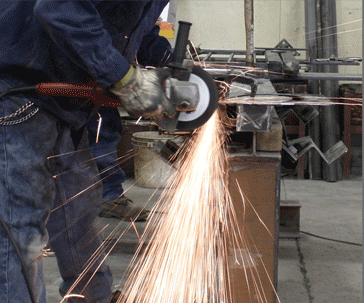

The fitting process, where grinding to ensure a close fit, tack welding, and then final welding happens by quality craftsmen.

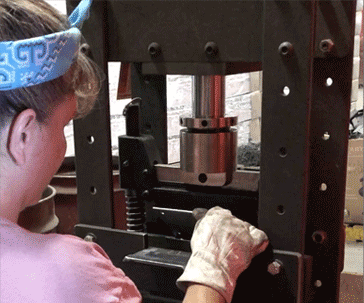

Our proprietary truss clips are cut, bent, and formed individually with hands-on care.

Trusses are welded, finished, and then inspected before going off to primer process.

Steel trusses are stacked and ready to be sent to primer for the final step before shipping out.