One of the most prominent and important features of Miracle Truss® buildings is the steel truss design we incorporate into them. You’ll see the details of the unique design in any of our buildings as it’s being put up. Our steel web trusses are designed to take advantage of the strength of dimensions and materials.

It’s such a strong and durable design that our buildings come with a 50-year structural warranty. The configuration of the trusses offers open, cathedral-like spaces. All of these features are made possible because of our chosen truss building material: Steel. Let’s take a closer look at this amazing material.

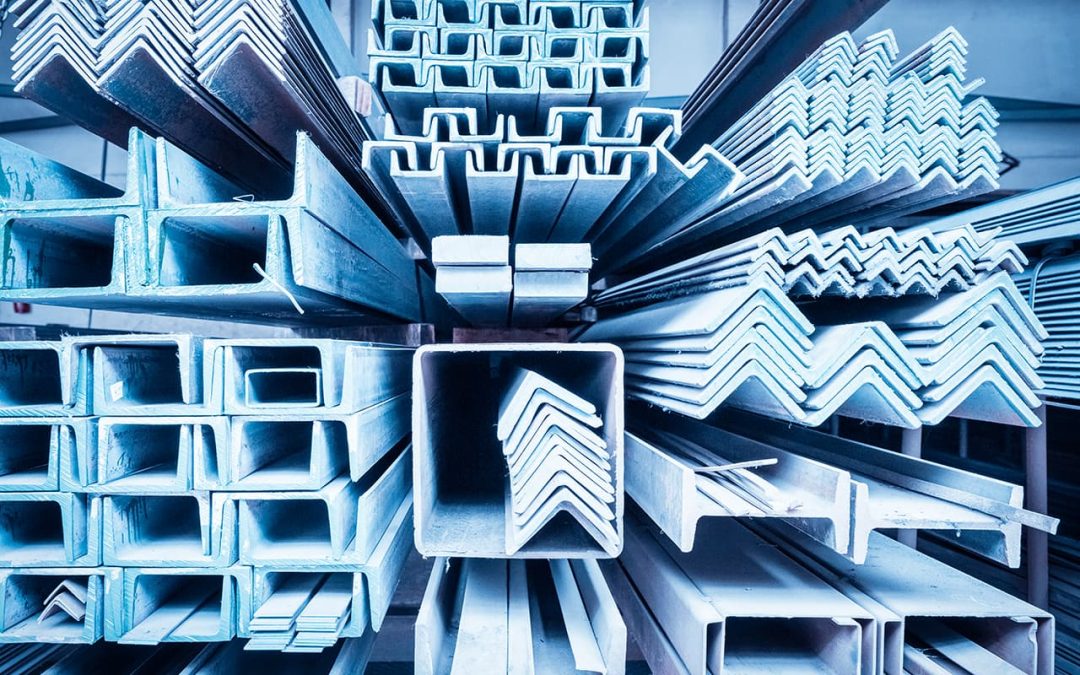

Amazing Variety

The World Steel Association says there are more than 3,500 different grades of steel. The standards and configurations can make you dizzy because of the number, but they help to break it down and to understand what you should look for in steel when making certain products.

There generally two main ingredients in most steel – iron and carbon. The amount of other ingredients – often called alloys – and impurities helps to determine the property of each steel grade. It’s far more precise, but if you’ve ever heard of a recipe calling for a “pinch” of an ingredient, you’ll understand the ratio of carbon to iron in the making of steel. The carbon content in steel can be anywhere from 0.1% to 1.5%, but the most commonly used grades of steel contain only about up to 0.25% carbon.

Although there are more than 3,500 grades of steel, most fall into just four main groups, which are based on their chemical compositions.

Carbon Steels

This is the biggest group, accounting for about 90% of total steel production. It’s probably easy to guess, but this group of steel is all about the relationship of carbon to iron. We’ve already talked about recipes, so let’s stay on that track with another cooking analogy.

If you’re a fan of cast iron cooking skillets, the carbon steel version is made of the same material but it’s either stamped or spun from sheets of steel – rather than created from molds. The higher amount of carbon allows for great strength without mass. That’s why it’s often used in construction materials.

Alloy Steels

This group of steels contain alloying elements, which are substances that allow us to manipulate the different properties found in steel. Depending on the alloy ingredient added to iron and carbon, you can change steels corrosion resistance, weldability, strength, and even its brittleness.

The most common alloying elements added to steel to create these characteristics include:

- Manganese

- Silicon

- Nickle

- Copper

- Chromium

- Aluminum

Stainless Steels

Even if you know little about metals, you’re probably aware that iron rusts. It’s a highly corrosive metal unless mixed with other elements. Stainless steel is mixed with carbon and the alloying element chromium to make it less prone to rust.

Creating a steel mixture that contains just 11% chromium can make it 200 times more resistant to rust and corrosion than regular steel.

Tool Steels

What a difference an alloy makes. Adding tungsten, cobalt, vanadium, or molybdenum to iron and carbon can drastically increase the metal’s durability and resistance to heat. This makes steel an ideal choice for drilling equipment and saws.

Steel really is a miracle substance. Its strength and durability compared to its weight makes it perfect as the supporting structure for your next building. You’ll also appreciate the difference in cost and the speed at which you can put it up and have it ready for use. View our galleries.